A progressive die in which two or more sequential operations are performed at two or more stations upon the work, which is moved from station to station. One operation is usually performed at each station. Can incorporate piercing, forming, extruding and drawing, and is usually applied to high quantity production runs.

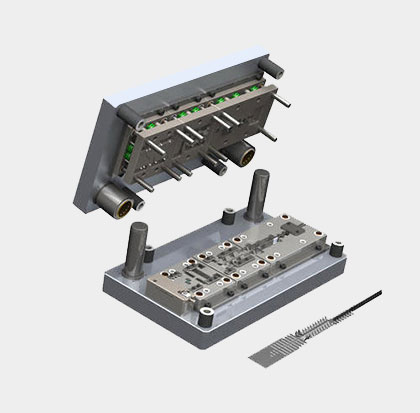

The progressive stamping die is placed into a reciprocating stamping press. As the press moves up, the top die moves with it, which allows the material to feed. When the press moves down, the die closes and performs the stamping operation. With each stroke of the press, a completed part is removed from the die.

While a progressive die can handle more than one operation at a time, it does so in several stages throughout multiple work stations. The progressive die’s main advantage is that it’s more efficient thanks to its high work speed and the reduced level of force.

While the multi-station design is more challenging to manage than the single-station unit, it’s easier for the progressive die to maximize punching productivity. That’s why engineers use progressive dies to make automotive parts, electronics and similarly complex components.